Mineralizer for natural stone

Definition Minéralisant TS

Mineral treatments for natural limestone are becoming increasingly popular. Historically, natural limestone has been treated with water repellents, which saturate the stone to make it less porous and less sensitive to stains. These treatments are not permanent and need to be reapplied regularly, especially on outdoor terraces. It is worth noting that 'TS' mineralizer stands for 'all surfaces,' a term often used by large retailers. Therefore, this type of product is a mineralizer for concrete, a mineralizer for travertine, and of course, a mineralizer for natural limestones from Burgundy.

The mineralizer is a non-film-forming solution that penetrates by capillarity and chemically transforms free lime and cavities into silica. It is a solution of silicon polycrystals. This reaction is called mineralization. The goal is to consolidate and waterproof all porous mineral substrates. The substrates are treated deeply thanks to the strong capillarity; furthermore, they are not sensitive to UV rays. The treated substrates are then more resistant to external damage and also easier to clean. The mineralizer also prevents efflorescence.

Water, energy, and chemical consumption are significantly reduced. The mineralization does not generate any decomposition waste, and the economic and environmental impact is significantly lowered. Furthermore, the mineralizer allows the materials to breathe, does not alter the slip resistance, and strengthens the substrate.

The silica formed during mineralization has a hardness of 7 on the Mohs scale, equivalent to quartz. Invented in 1812 by the German mineralogist Friedrich Mohs, the Mohs scale is used to determine the relative hardness of materials based on 10 well-defined minerals with varying hardness. This (non-linear) scale is graded from 1 to 10 (1 corresponds to talc, 3 to calcite, 7 to quartz, and 10 to diamond).

At Comptoir des Pierres, we like to take a step back on new treatments, and we have applied a mineralizer to various Burgundy limestone products, including our paving stones and slabs in our Comblanchien outdoor showroom. After two years of testing and two winters in Burgundy, we are convinced of the effectiveness of this product.

Limestone treatment - What chemistry ?

To have a broader view of natural limestone treatments, it is important to understand that treatments are grouped into two main categories :

–Organic chemistry : most often based on petroleum, from which resins, silicones, varnishes, bitumens, etc. are derived. This chemistry is renewable, but the treatment needs to be reapplied regularly. Our product Imperpierre falls into this category.

–Inorganic chemistry : It is cold liquid glass that penetrates the materials by capillarity to mineralize them. The mineralization reaction is permanent. It should be done once in the lifetime of the material (in one or more coats, depending on the porosity of the limestone). Our mineralizer falls into this category.

Causes of wear in natural limestone

Weather conditions (sun, rain, snow, salt, pollution, etc.) and regular maintenance affect the materials. Water that penetrates the materials accelerates the growth of moss and their degradation due to freezing.

De-icing salts and sea salts penetrate the capillary networks, which can disintegrate the substrates. Thermal shocks and UV rays are also reasons for premature wear of the materials.

Unprotected porous surfaces will be more sensitive to the impregnation of pollutants and various stains.

Use of the mineralizer - Protection

Given its higher price compared to a water repellent, we recommend it on a case-by-case basis depending on the projects, either as a preventive measure or for restoration.

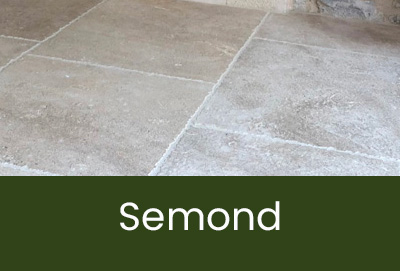

Some examples : disintegration of old limestones to reinforce them, choosing Massangis or Semond stone for outdoor use, installing stones in areas exposed to high humidity (cellars, basements, etc.), marine or mountainous environments (sea spray, snow, etc.), heavy presence of trees above your terrace or pool deck, frequent maneuvering of heavy vehicles on paving stones (which helps clean tire marks or tar, etc.).

Some references of use in France: Musée de l'Orangerie (Paris), Château La Coste (Bouches-du-Rhône), Paris Airports, City of Dijon...

Feel free to explain your project to us, and we will be able to recommend the best option between a water repellent and a mineralizer.

Application of the water -Repellent mineralizer

On a clean surface, apply the mineralizer to saturation using a sprayer (or a roller, and even a brush for small surfaces), 1 to 2 coats (depending on the porosity), with a minimum interval of 30 minutes between coats. After application, let it penetrate for 15 minutes and wipe off the excess with absorbent paper.

Always perform a test before any final treatment. The mineralizer is ready to use. Do not mix it with any other product. Protect all surfaces that the product is not intended for (gutters, openings, verandas, etc.). Do not apply in direct sunlight, during freezing weather, or when there is a risk of freezing within the following hours.